SPOILER ALERT!

Improving Performance: Optimizing Your Assembly Line With Tunnel Pasteurizers

Short Article Produced By-Dempsey Cohen

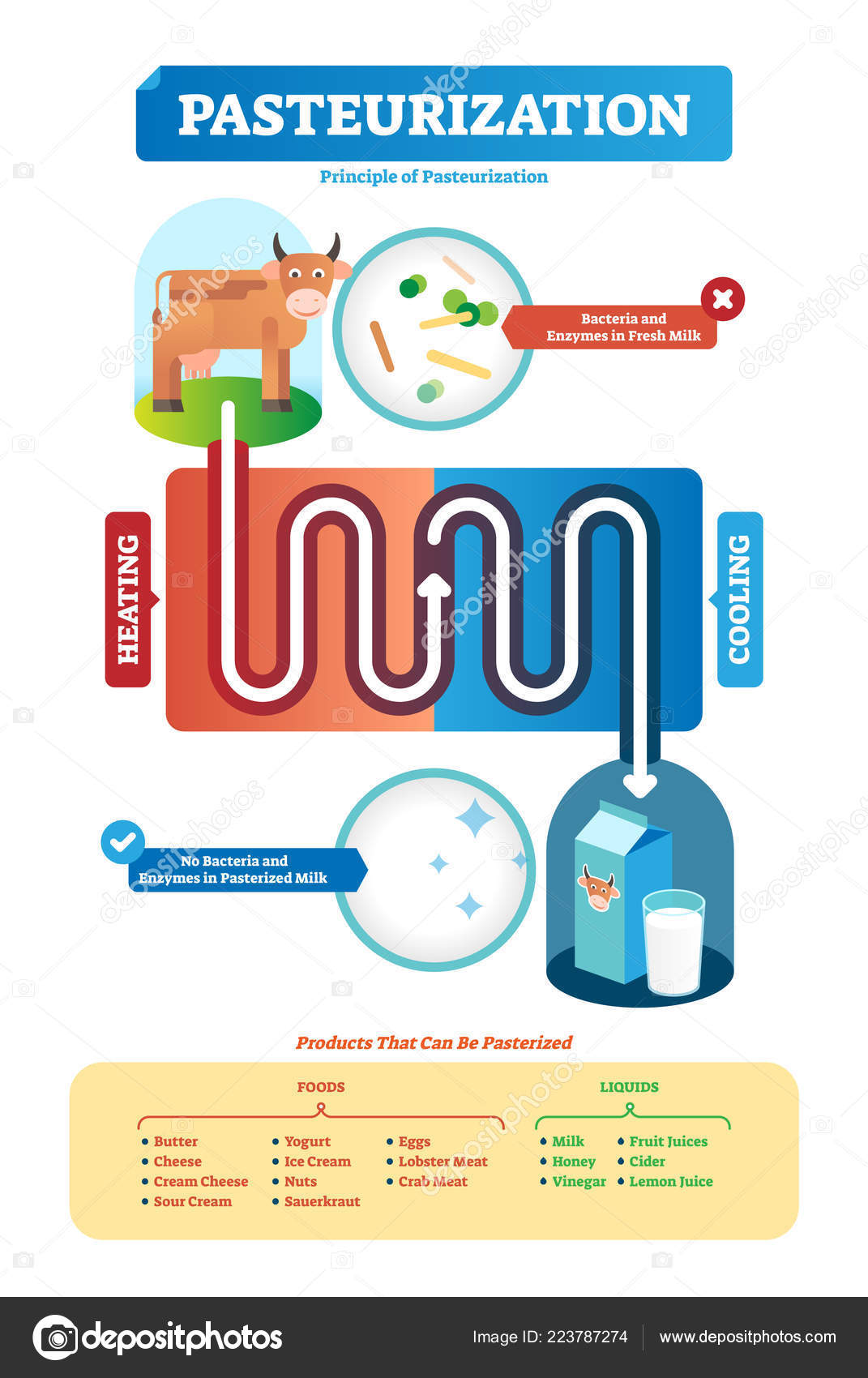

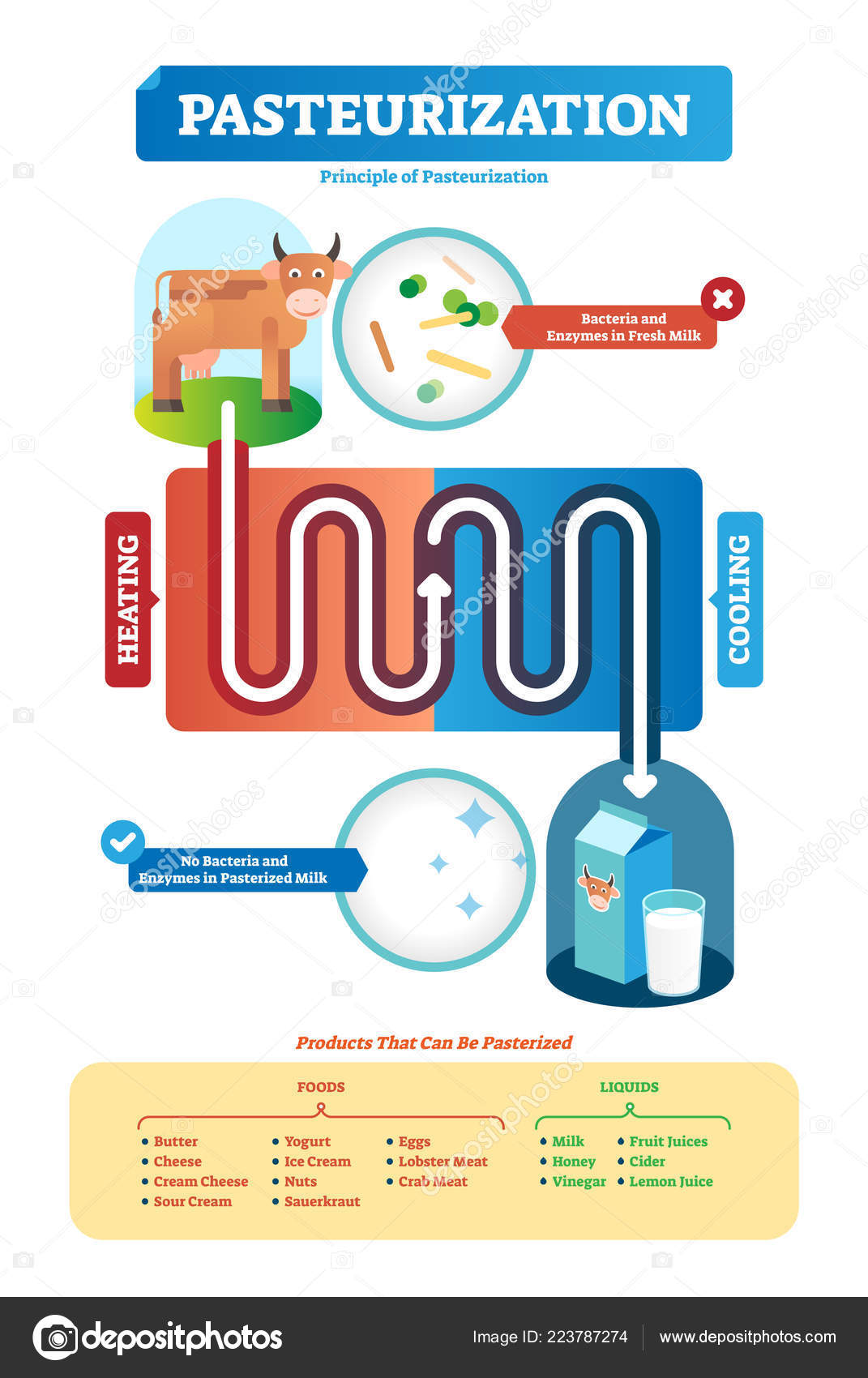

Tunnel pasteurizers are large industrial-scale machines that heat and trendy beverages in order to eliminate microorganisms and expand their service life. Their effectiveness depends on accuracy control.

Several drink companies have actually retrofitted their existing Tunnel pasteurizers with new eco-friendly modern technologies to accomplish significant ecological benefits. These include reduced power usage, lower water use and lowered greenhouse gas discharges.

When you run a brewery, your objective isn't just to eliminate dangerous pathogens, yet also to provide uniformity in your products. A well-executed pasteurization procedure not only prolongs beer's life span, however it guarantees that every container of your beer will taste the exact same, from your very first set to your last. This is particularly important for craft breweries looking to draw in health-conscious clients who desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers work by bringing bottles and cans approximately their wanted temperature in stages, holding them there for long enough to kill off the bacteria that cause putridity. They after that bring them down once more in step-by-step steps up until they get to space temperature level, maintaining taste accounts. By doing this, they not just prevent bacteria from increasing in the item, however they additionally lower power usage by eliminating warm loss. These are the kinds of efficiency gains that can accumulate swiftly.

As even more emphasis is positioned on eco-friendly production methods, drink suppliers are seeking means to minimize their waste production. Tunnel pasteurizers do a fantastic task of this, especially when they are developed and built by seasoned experts.

Tunnel pasteurizers make use of a series of sprays to heat the bottles or canisters as they relocate with the maker. This gets rid of the need for a big heavy steam storage tank that consumes power and wastes water. Additionally, Tunnel pasteurizers make use of a water financial savings system to recycle the warm water used in the home heating procedure, which minimizes water and sewer usage.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft makers who want to prolong their products' life span and guarantee consistency between batches. Unlike flash pasteurizers, which in some cases struggle with high levels of carbonation, Tunnel devices can deal with these effervescent concoctions without breaking a sweat (or a container).

When your drinks are correctly treated in Tunnel pasteurizers, they're protected from dangerous bacteria while preserving their flavor accounts. This implies your brews, sodas, acid preserves (like fruits or acids), and health and wellness shots can extend their shelf life without shedding their signature taste.

In order to accomplish this, passages include precise temperature control and even distribution throughout their several stages. Furthermore, conveyor belt speeds assist make certain equivalent therapy times for each bottle entering the machine. All this aids you assure high quality results every time.

Finally, passages are compatible with carbonated beverages, an expanding pattern amongst health-conscious consumers searching for fizzy options to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel machines are made to manage them.

Moreover, https://www.cmaj.ca/content/re-double-insurance-holder-pasteurization-and-human-milk-itself-guarantee-safety with energy recuperation systems reduces water usage as well. By using the retrieved water for cooling, you'll considerably cut your power consumption and greenhouse gas exhausts.

Tunnel pasteurizers are energy-intensive machines, yet you can lower your energy consumption by retrofitting them with advanced eco-friendly innovation. This consists of solar-powered heating elements that can work on renewable energy sources, lowering dependence on nonrenewable fuel sources and your carbon impact.

One more great attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern among today's health-conscious consumers. Unlike flash pasteurizers, which often deal with high-carbonation levels, Tunnel systems can take care of these fizzy mixtures easily.

zPasteurAIzer can keep track of the efficiency of your current Tunnel pasteurizer by approximating the accumulated product top quality (PU) worth for every set. This enables you to determine if your present temperature level control system is providing sufficient warmth therapy along with determining any kind of curved spray heads. You can after that adjust the equipment settings based upon your favored PU worths, enhancing manufacturing performance while lowering power usage. This is a terrific way to lower your water consumption as well, aligning your company with consumer demand for eco responsible products.

Tunnel pasteurizers are large industrial-scale machines that heat and trendy beverages in order to eliminate microorganisms and expand their service life. Their effectiveness depends on accuracy control.

Several drink companies have actually retrofitted their existing Tunnel pasteurizers with new eco-friendly modern technologies to accomplish significant ecological benefits. These include reduced power usage, lower water use and lowered greenhouse gas discharges.

1. Raised Efficiency

When you run a brewery, your objective isn't just to eliminate dangerous pathogens, yet also to provide uniformity in your products. A well-executed pasteurization procedure not only prolongs beer's life span, however it guarantees that every container of your beer will taste the exact same, from your very first set to your last. This is particularly important for craft breweries looking to draw in health-conscious clients who desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers work by bringing bottles and cans approximately their wanted temperature in stages, holding them there for long enough to kill off the bacteria that cause putridity. They after that bring them down once more in step-by-step steps up until they get to space temperature level, maintaining taste accounts. By doing this, they not just prevent bacteria from increasing in the item, however they additionally lower power usage by eliminating warm loss. These are the kinds of efficiency gains that can accumulate swiftly.

2. Lowered Waste

As even more emphasis is positioned on eco-friendly production methods, drink suppliers are seeking means to minimize their waste production. Tunnel pasteurizers do a fantastic task of this, especially when they are developed and built by seasoned experts.

Tunnel pasteurizers make use of a series of sprays to heat the bottles or canisters as they relocate with the maker. This gets rid of the need for a big heavy steam storage tank that consumes power and wastes water. Additionally, Tunnel pasteurizers make use of a water financial savings system to recycle the warm water used in the home heating procedure, which minimizes water and sewer usage.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing point for craft makers who want to prolong their products' life span and guarantee consistency between batches. Unlike flash pasteurizers, which in some cases struggle with high levels of carbonation, Tunnel devices can deal with these effervescent concoctions without breaking a sweat (or a container).

3. Much Better Item Quality

When your drinks are correctly treated in Tunnel pasteurizers, they're protected from dangerous bacteria while preserving their flavor accounts. This implies your brews, sodas, acid preserves (like fruits or acids), and health and wellness shots can extend their shelf life without shedding their signature taste.

In order to accomplish this, passages include precise temperature control and even distribution throughout their several stages. Furthermore, conveyor belt speeds assist make certain equivalent therapy times for each bottle entering the machine. All this aids you assure high quality results every time.

Finally, passages are compatible with carbonated beverages, an expanding pattern amongst health-conscious consumers searching for fizzy options to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel machines are made to manage them.

Moreover, https://www.cmaj.ca/content/re-double-insurance-holder-pasteurization-and-human-milk-itself-guarantee-safety with energy recuperation systems reduces water usage as well. By using the retrieved water for cooling, you'll considerably cut your power consumption and greenhouse gas exhausts.

4. Decreased Power Consumption

Tunnel pasteurizers are energy-intensive machines, yet you can lower your energy consumption by retrofitting them with advanced eco-friendly innovation. This consists of solar-powered heating elements that can work on renewable energy sources, lowering dependence on nonrenewable fuel sources and your carbon impact.

One more great attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern among today's health-conscious consumers. Unlike flash pasteurizers, which often deal with high-carbonation levels, Tunnel systems can take care of these fizzy mixtures easily.

zPasteurAIzer can keep track of the efficiency of your current Tunnel pasteurizer by approximating the accumulated product top quality (PU) worth for every set. This enables you to determine if your present temperature level control system is providing sufficient warmth therapy along with determining any kind of curved spray heads. You can after that adjust the equipment settings based upon your favored PU worths, enhancing manufacturing performance while lowering power usage. This is a terrific way to lower your water consumption as well, aligning your company with consumer demand for eco responsible products.